Environmental Materials Division

Business Contents

Technology for Improving Corrosion Resistance of Steel

Kyoto Materials promotes technology development and practical application to prevent corrosion of steel and other materials. The method commonly used to prevent corrosion is by painting to block the corrosive environment, but the corrosive environment penetrates through the paint film causing corrosion of iron and maintenance of the paint film becomes a problem. The Environmental Materials Division is engaged in research and development of methods and materials to prevent corrosion by providing a spontanious corrosion product coating to the steel surface with the help of the environment instead of blocking the environment.

Research & Development Field

| Environmental Materials Laboratory em-lab@kyoto-materials.jp |

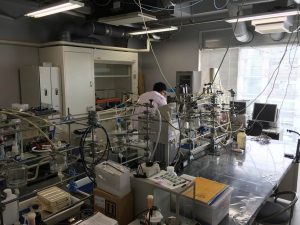

Reseach Laboratory |

|

|

Product Information

Pat!naLock®

Reactive paint that significantly improves corrosion resistance of steel materials – Pat!naLock®

For corrosion protection of iron materials, paint is generally used to shield iron from the corrosive environment, but the corrosive environment penetrates through the paint film causing corrosion of iron. Since iron is present inside the earth’s crust in the form of iron oxide (iron ore), iron always tries to return to the form of iron ore. From the human perspective, this appears as corrosion, but from the perspective of nature iron is returning to the earth. This is known as rusting. That is, in the case of paint film that normally aims to provide an environmental shield, peeling of the paint film starts due to the corrosion of the base metal by the invasion of corrosive factors because of either paint film deterioration or pinhole defect, and repairs such as repainting is required causing the life cycle cost of steel structures to increase.

Reactive paint Pat!naLock® reacts strongly with iron and the corrosive environment creating a highly corrosion-resistant oxide layer mainly made of rust on the iron surface suppressing the corrosion of iron. In other words, Pat!naLock® harmonizes with the natural environment and returns iron surfaces to their original form that is oxide, due to which iron settle downs and does not rust, and this essentially suppresses further corrosion.

Pat!naLock® is applied to the steel surface. Corrosion is prevented from advancing by promoting the formation of an oxide layer on the iron & steel or zinc plated steel surfaces by setting the oxide layer that is formed to a state of high corrosion resistance. The reactive paint can be applied with normal methods such as spraying, brush coating, and roller coating without any special preparations.

This product can be applied to not only a wide range of newly constructed steel structures such as bridges and steel towers, and various plant facilities but also to existing structures without completely eliminating residual rust such as red rust. The reactive paint can be applied after a hard-cleaned finish of surface preparation.

RustLess

~ Rust inhibitor film for professional molds ~

RustLess a high-performance rust inhibiting film. Just by wrapping metal products with RustLess prevents rusting for a long time.